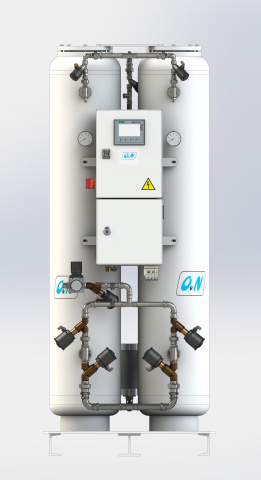

OVN series oxygen generators extract available oxygen from ambient air from other gases using pressure swing adsorption (PSA) technology. During the PSA process, compressed and subsequently cleaned ambient air is fed into the ZEOLIT molecular sieve, which allows oxygen to pass through as a product gas and at the same time adsorbs other gases. The zeolite releases the adsorbed gases to the atmosphere when the outlet valve is closed and the adsorbent screen pressure returns to ambient pressure. Subsequently, the adsorption screen will be flushed with oxygen before the fresh compressed air enters the new production cycle. To guarantee a constant product flow, OVN oxygen generators use modules of two pressure vessels with ZEOLITH, which alternately switch between adsorption and regeneration phases. Under normal operating conditions and with proper maintenance, the PSA generator will have an almost unlimited life.

Advantage for the client

- amortized costs in less than 2 years. O2 costs 1.0-1.2 KW/m3

- The PSA O2 generator is designed to be easily installed in any location, requiring only compressed air lines and a power source

- independence from liquid oxygen suppliers and associated logistical problems and ever-increasing costs

- no dangerous handling and storage of pressure vessels with liquid oxygen

- we will make a generator exactly according to your requirements

Characteristics for standard generators

- operating pressure up to 10 bar

- operating temperature range 5 to 35 °C

- ambient air temperature. range up to 45 °C

- dew points (atmospheric) -60 °C

- performance 1.02 to 94.9 Nm3/h, on order up to 10 tons/day

- purity up to 95%

Models PSA O2 generators standard

- O2 GEN basic

- O2 GEN 1

- O2 GEN 2

- O2 GEN 3

- O2 GEN 4

- O2 GEN 5

- O2 GEN 10

- O2 GEN 16

- O2 GEN 29

- O2 GEN 35

- O2 GEN 44

- O2 GEN 57

- O2 GEN 75

Use of PSA generators

- Aquaculture - wastewater treatment plants

- Hospitals

- Veterinary clinics

- Laboratories

- Propellant gas for ozone generators

- Glass production (blowing)

- Leaching

- Reduction of NOx emissions for fuel burners

- Mining of precious metals and minerals with the help of oxygen

- Welding, cutting and brazing

- Wellness

- Fish farming

- Metallurgy

- Mining

CERTIFICATION: ISO 9001/2015 a ISO 13485/2016 medical

Limited

Limited